Composting Organic Waste to Make Commercial Organic Fertilisers

'Harvest Power' and other companies throughout the world are attracting Government grants to develop commercial processes to convert organic waste into commercial fertilizers. Many of the processing units for organic waste resemble the humble domestic composting bins. These companies recycle organic waste products such as food scraps, garden lawn clippings and trimmings, scrap wood and other organic waste products to produce produces electricity and natural gas (methane), as well as soil conditioners and organic fertilizer products.

Harvest Power that has facilities in California, Pennsylvania, Ontario and British Columbia, was recently added to the prestigious Cleantech 100 list of Top Global Cleantech companies and was granted $51 million to further develop its technologies and to expand its platform throughout North America.

Composting of Organic Wastes

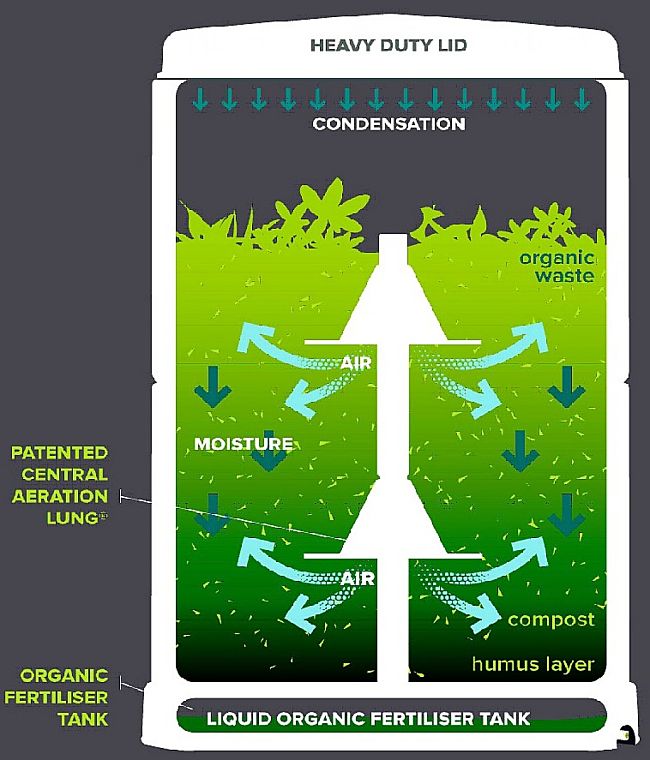

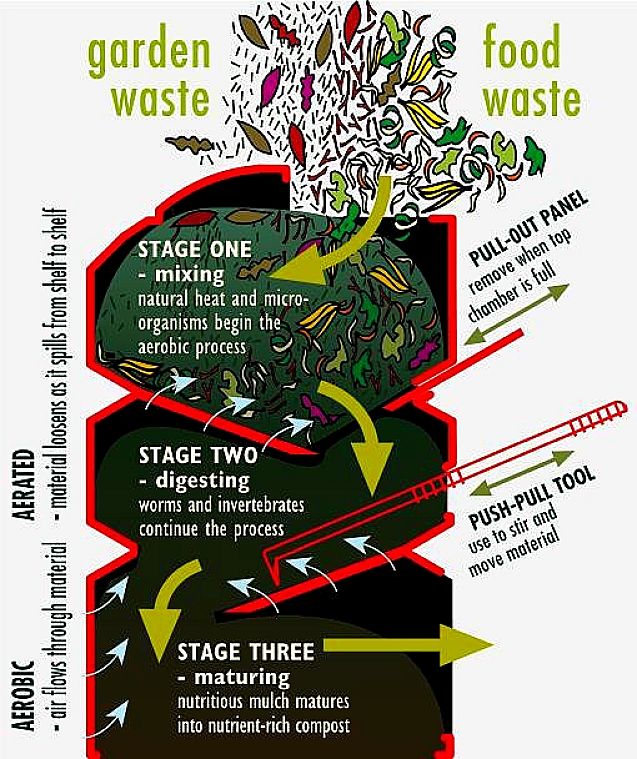

Harvest Power's proprietary Covered Aerated Static Pile system employs state of the art composting processes that maximize efficiency while minimize odours. It is highly effective and produces none of the odour problems that have plagued the traditional enclosed and windrow and compost systems. The process yields high-quality organic fertilizers and garden-ready compost. The aeration reduces the need to turn-over the compost pile and reduces the bad odours produced by anaerobic digestion in the compost pile.

Most gardeners are very familiar with the composting processes involved which has been adapted for the commercial production of fertilizers.

Anaerobic Digestion

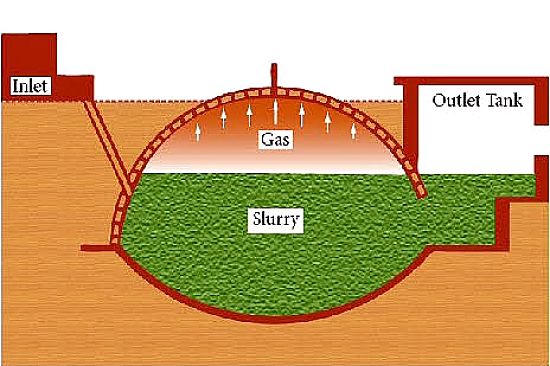

Harvest Power also uses naturally occurring microorganisms to anaerobically break down waste to produce biogas, which is a mixture of carbon dioxide and methane. Once again this a very familiar process that is used domestically and for processing dairy, sugar cane and pig waste into energy for use on the farm.

The commercially produced biogas can be burnt to produce clean and renewable electricity. The biogas gas can also be further processed to domestic natural gas supply standards for use in the home. It can also be used to make compressed natural gas (CNG) fuel.

The company has developed two processes for different types of organic wastes:

Low solids anaerobic digestion - for fluid and pumpable organic waste slurries like manure, various wastewaters and pulped food wastes that have less than 20% entrained solids. These semi-liquid materials are filtered and the fine solids blended before being mixed with water and heated. The innoculum of micro-organisms is added to begin the digestion process. The solution is pumped into a chamber where the organic materials are anaerobically digested yielding biogas production occur. After digestion the remaining solids are filtered from the liquids. These solids are either pelletized for use as soil conditioners land or are either composted. The remaining liquids are sent through a wastewater treatment system. Many similar low solids anaerobic digestion systems are already used throughout the world for municipal wastewater treatment and for organic wastes from dairy farms and piggeries.

High solids anaerobic digestion – This also known as “dry fermentation”. It is used best for solid materials like dense food waste, garden clippings and yard debris that have a solids contents range from a quarter to a half of the material. The materials are loaded into digestion chambers and left to digest for two weeks, after which the partially digested material is transferred to the aerobic compost system for further processing.

The production of organic fertilisers and anaerobic digestion from organic waste materials has many advantages:

- Diverts useful waste organic materials from landfills and incinerators

- Generates clean renewable energy.

- Restores and maintains healthy soils using compost products

- Replaces non-renewable chemical fertilizers that are made from mined minerals of from oil.

- Creates local, green jobs in the community.

These technologies have many applications in developing countries. One of the major deficiencies in agricultural soils in Guam and other tropical region in the Pacific is the low inherent organic matter content that reduces production and degrades the soil structure. Composted organic material is being applied on experimental agricultural fields in Guam to enhance soil nutrients and organic matter contents and to improve the chemical and physical properties of the soils used for agriculture.

In a pilot project in Guam, compost is produced from ground vegetation debris that is mixed with: fish feed, shredded paper, animal manure and other organic wastes. The processed compost is then applied to the corn fields at the rate of; 0, 30, 60 and 120 tons per acre. All applications greatly increased yields, with the exception of the highest rate of !20 tons per acre. The study concluded that the use of composed organic material as the main source for a soil fertility program was practical in the Pacific islands. Developing these farming practices into a sustainable agricultural system was also feasible but the economics needs to be further examined.

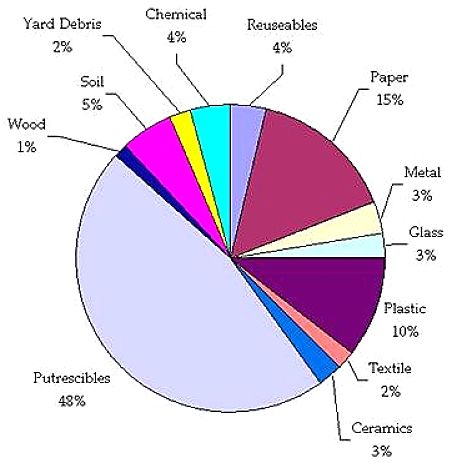

Several studies in the Philippines have found that domestic house-hold waste contains 50% - 60 % ends organic waste that is dumped as land fill. Also the farms that surround major urban centres in the Philippines also produce large amounts of organic waste which are either burned (as in the case of rice stalks and rice hull) or are dumped in landfills. The lowest cost means of processing this organic waste is to just simply collect the organic material, shred it, pile it up, and let nature take its course. In one to three months month the compost can be used on the farms. The speed and quality of the compost can be greatly enhanced if the right 'bugs' are added.

The Agricultural Inoculants Corporation of the Philippines has produced an additive for a project that cost P50,000. For a net cost of $1,200 per bag, the AIC microbial rapid composting agent yields about 2,000 kg of complete high-grade organic fertilizer. The organic fertilizer that is produced costs P100 per bag or about $2 per bag, about half the cost of other commercial organic fertilizer in the Philippines which is about P200 or P250 per bag.

This a good example where simple back-yard domestic processes can be geared up to provide commercial scale products.

In Australia many municipal councils have developed Organics Resource Recovery Facilities. One of the first was developed at Port Macquarie on the north Cast of New South Wales the material collected from the green bins picked up from the kerbside is mixed with mulched bulk green organic materials. It is chopped, shredded and combined with solid sewage sludge from Council's Sewage Treatment Plant. The material is placed in temperature and humidity controlled tunnels to hasten the decomposition process. Air is driven through the organic material via pumps fed into the base of the tunnel and recycled process water is added via sprays at the top of the tunnels when required. All exhaust gases from the composting tunnels are passed through Biofilter unit to remove odours and to filter our any particulates. The compost is removed from the tunnels after about 4 weeks and stored in the open air to dry out. This composted product is available for sale from the site. However, as with all domestic waste products there is a high risk of contamination and this reduces its use. Most of the material is used for council parks and gardens. It is not suitable for use on agricultural lands.